Would you like to make this site your homepage? It's fast and easy...

Yes, Please make this my home page!

Valve Tappet Adjustment

Excessive valve clearance will cause tappet noise and negative

clearance will cause valve damage, excessive wear of the cam follower,

and loss of power.

Therefore, the valve tappet clearance should be maintained

properly.

- Turn the fuel valve to the "STOP" position, remove

the fuel lines from the fuel valve body, raise the seat and remove

the fuel tank.

- Remove the cylinder head cover A (inlet side) and B (exhaust

side).

- Remove the point cover and the dynamo cover.

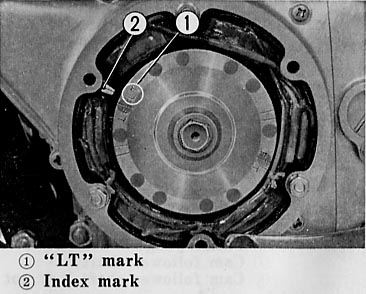

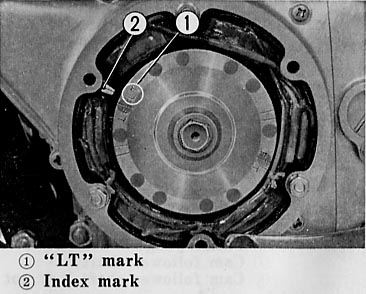

- Rotate the generator rotor counterclockwise and align the

"LT" mark (1) on the generator rotor with the index

mark (2) on the stator. If the index marks of both the inlet

and exhaust camshafts are aligned to the index marks on the bearing

holders, this position is the top dead center of the intake stroke,

therefore, the rotor should be turned one complete revolution

to bring it to the top dead center of the compression stroke,

in other words, the purpose is to place the left hand piston

at the top dead center of the compression stroke.

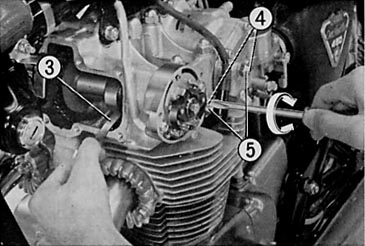

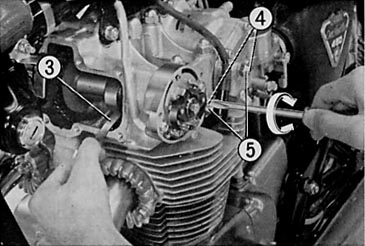

- Check the left hand cylinder tappet clearances in the exhaust

and inlet valves. Insert the feeler gauge (3) between the cam

and the cam follower. If a slight drag or resistance is felt

as the gauge is inserted, the clearance is correct. If the clearance

is too close or too loose, adjust the tappet. The standard clearance

for both the inlet and exhaust valves is 0.0012 in. (0.03

mm) when the engine is cold. Adjustment by loosening the

cam follower shaft lock nut (5) and turning the cam follower

shaft (4) with a screw driver as shown in the photo. Specific

clearance can be obtained at two positions of the follower shaft,

but only one of these is the correct adjustment point.

The clearance is reduced when the adjustment is made as shown

in the table below.

|

Right side |

Inlet: |

Turn counterclockwise |

| Exhaust: |

Turn clockwise |

|

Left side |

Exhaust: |

Turn counterclockwise |

| Inlet: |

Turn clockwise |

NOTE: The check or adjustment of the tappet clearance should

be performed while the engine is cold. The clearance may tend

to increase as the temperature rises. Make sure that the adjustment

has not been disturbed while tightening the lock nut, by rechecking

the clearance after the lock nut has been tightened.

- Next, rotate the generator rotor 180° counterclockwise

to bring the right hand piston to the top dead center of the

compression stroke and then check both the right inlet and exhaust

valve tappet clearances in the same manner as for the left hand

side.

HOME CB 450

K5 information CB

450 K5 Manual: Table of Contents